IEC61347-1 Annex D Requirements for carrying out the heating tests of thermally protected lamp controlgear

IEC61347-1 HEATING ENCLOSURE FOR THERMALLY PROTECTED BALLASTS is made according to IEC61347-1 Annex D

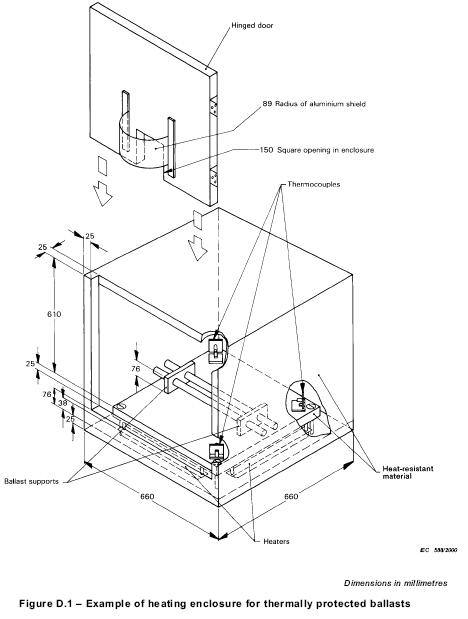

The heating tests are made in an enclosure in which the temperature of the ambient air is maintained as specified (see Figure D.1). The entire test enclosure shall be constructed of heat resistant material 25 mm thick. The test compartment of this enclosure shall have internal dimensions of 610 mm × 610 mm × 610 mm. The floor of the test compartment shall measure 560 mm × 560 mm, permitting an air space of 25 mm all around the platform for

circulation of the heated air. A 75 mm heater compartment shall be provided below the floor of the test area for the heating elements. One side of the test compartment may be removable, but shall be so constructed that it can be securely fastened to the remainder of the enclosure. One of the sides shall have a 150 mm square opening located centrally at the bottom edge of the test compartment, and the enclosure so constructed that the only possibility of air circulation will be through this opening. The opening shall be covered by an aluminium shield as shown in Figure D.1.

The heat source used for the test enclosure described above shall consist of four 300 W strip heaters having approximate heating surface dimensions of 40 mm × 300 mm. These elements shall be connected in parallel to the supply source. The elements shall be mounted in the 75 mm heater compartment midway between the test compartment floor and the base, and so arranged that they form a square with the outside edge of each element 65 mm from the adjacent inside wall of the enclosure. The elements shall be controlled by a suitable thermostat.

Specifications:

- Working room dimension: 610×610×610mm

- Temperature range: RT+10℃—+100℃

- The floor of the test compartment : 560×560mm

- Materials of inner and outside chamber: Senior stainless steel

- Insulation Material: Ultra-fine glass wool insulation material

- Heater: Dedicated strip heater (heating surface area of 300 × 40 mm), each group three hundred watts, a total of four groups, with the power supply in parallel.

- Special wooden test sample holder

- Third gear temperature measurement points (at any time monitoring and conversion)