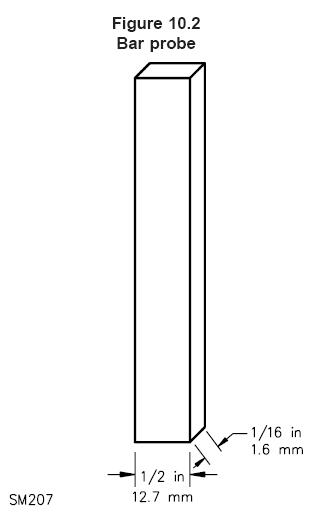

Bar probe UL1278 Figure 10.2 SM207 :

Standard requirement: UL1278 Figure 10.2 and UL1278 chapter 10 Guarding of Heating Elements

Product details:

It conforms to standard requirement of UL1278 Fig 10.2. The handle is made of nylon and the probe is made of stainless steel.

Application:

The heating element and any part of the element assembly (such as an element support, sheath and similar parts) shall be so guarded that flammable material as well as persons will be protected against contacting it.

Test sample:

Heating elements.

Feature:

Nylon handle + probe, it is manufactured according to the standard figure.

Reference Standard of UL1278 below:

10 Guarding of Heating Elements

10.1 General

10.1.1 The heating element and any part of the element assembly (such as an element support, sheath,

and similar parts) shall be so guarded that flammable material as well as persons will be protected against contacting it.

10.1.2 Any heater projections such as guards or grilles that are intended to guard hot heater surfaces

shall be positively secured to the heater such as by screws, rivets or welding or being engaged in slots

so that they cannot be removed without the use of tools, breaking or permanent bending or distortion.

10.1.3 The acceptability of a guard is judged with respect to its general serviceability and with respect to

the shape and size or both of the openings in it, in conjunction with the distance of the guard from the

heating element and the other high-temperature parts mentioned in 10.1.1. Except as noted in 10.1.5, an

opening in a guard is considered to be acceptable if, with the heater in any intended operating position,

the following conditions are met:

a) The shape and size of an opening are such that a test gauge in the form of a right-circular

cone having a base diameter of 2-3/4 inches (69.9 mm) and an altitude of 5-1/2 inches (139.7mm), see Figure 10.1,is prevented from touching the heating element and the other hightemperature parts when the cone probe is inserted, apex first, in any manner. See 10.1.4.

b) The shape and size of an opening which permits the vertically downward entrance of a bar probe 1/2 inch (12.7 mm) wide and 1/16 inch (1.6 mm) thick, see Figure 10.2, are such that a triangle probe 1/16 inch thick and in the form of an isosceles triangle having a base of 2-3/4

inches and an altitude of 5-1/2 inches, see Figure 10.3, is prevented from touching the heating

element and the other high-temperature parts when the triangle probe is inserted, apex first, in

any manner. The testing of an opening with the triangle probe applies also where the vertically

downward insertion of the bar is prevented by the construction of the guard, the use of an

additional barrier, or both, unless the vertically applied bar tends to be deflected outward – that

is, away from the guard.

c) The area of an opening in a substantially vertical face of a guard is not more than 3-1/4

square inches (2100 mm2 ) if the size and/or shape of the opening permits the entrance from

any horizontal direction of a vertically oriented rod probe 1/16 inch in diameter and 2-3/4 inch

long, see Figure 10.4. Also, see Figure 10.5.