This probe conforms to standard requirement of

UL398 Figure 8.2(PA170B)、

UL507(PA170D)、

UL749 Figure 2、

UL982 Figure 58.6 and

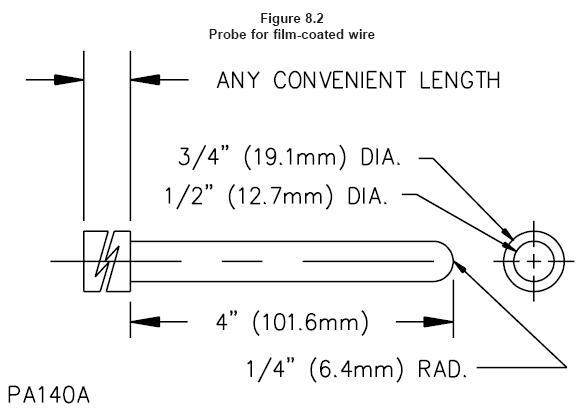

UL1278 Figureure 8.2(PA140A). It is used for the enamel wire.

The handle is made of Nylon while the probe is stainless steel.

8 Accessibility of Live Parts

8.1 An electrical part of a heater shall be so located or enclosed that protection against unintentional

contact with uninsulated live parts will be provided, except that this requirement does not apply to a visibly glowing open-wire element and the connections immediately adjacent to the element. See 3.1, 8.2, 32.7

and 32.14. Insulated motor brush caps do not require additional enclosures.

8.2 The requirement in 8.1 does not apply to the sheath of an isolated metal-clad element in a heater

having provision for grounding the enclosure, although such a sheath is considered to be a bare live part when spacings are being measured.

8.3 In determining if an opening in an enclosure is acceptable, consideration is to be given to:

- a) The proximity of uninsulated live parts (as determined by applying 8.1, 8.2, 8.4, 8.5, and

8.15 and

- b) The possibility of the emission of burning insulation, molten metal, and similar materials

through the opening (as determined by applying 7.3 – 7.6.)

8.4 To reduce the likelihood of unintentional contact that may involve a risk of electric shock from an

uninsulated live part or film-coated wire, an opening in an enclosure shall comply with either (a) or (b).

- a) For an opening that has a minor dimension (see 8.8) less than 1 inch (25.4 mm), such a part or wire shall not be contacted by the probe illustrated in Figure 8.3.

- b) For an opening that has a minor dimension of 1 inch or more, such a part or wire shall be

spaced from the opening as specified in Table 8.1.

Exception: An integral enclosure of a motor need not comply with these requirements if it complies withthe requirements in 8.5.

8.5 With respect to a part or wire as mentioned in 8.4, in an integral enclosure of a motor as mentioned

in the exception to 8.4:

- a) An opening that has a minor dimension (see 8.8) less than 3/4 inch (19.1 mm) is acceptable

if:

1) Film-coated wire cannot be contacted by the probe illustrated in Figure 8.2;

2) In a directly accessible motor (see 8.9), an uninsulated live part cannot be contacted

by the probe illustrated in Figure 8.4; or

3) In an indirectly accessible motor (see 8.9), an uninsulated live part cannot be contacted by the probe illustrated in Figure 8.1.

b) An opening that has a minor dimension of 3/4 inch (15.1 mm) or more is acceptable if a part

or wire is spaced from the opening as specified in Table 8.1.

This is generated text for figtxt.

8.6 The probes mentioned in 8.4 and 8.5 and illustrated in Figures 8.1, 8.2, 8.3, and 8.4 shall be applied to any depth that the opening will permit; and shall be rotated or angled before, during, and after insertion through the opening to any position that is necessary to examine the enclosure. The probes illustrated in Figures 8.3 and 8.4 shall be applied in any possible configuration; and, if necessary, the configuration shall be changed after insertion through the opening.